Non-alcoholic (NA) beer has gone from a niche afterthought to one of the fastest-growing categories in beverage alcohol. Brewers are responding to rising consumer demand for flavorful, healthier, and midstrength options. But making a great-tasting NA beer is a technical challenge—one that requires careful ingredient selection and process control.

Let’s break down the core methods commercial brewers are using to produce non-alcoholic beer, and the pros and cons of each approach.

Please note: We always recommend pasteurization or other methods of control to prevent re-fermentation and to increase shelf stability with all NA production methods.

Maltose-Negative Yeast Method

The most practical approach that can be implemented without additional processes or equipment

Overview: Use a specialized yeast strain (like Fermentis SafBrew LA-01™) that only ferments glucose—not maltose or maltotriose—so the beer naturally stays below 0.5% ABV, while still developing some fermentation character.

Pros:

- Doesn’t require expensive de-alcoholization equipment—works in standard fermentation vessels

- Produces NA beer with more authentic beer-like aroma and flavor than arrested fermentation

- Faster, more scalable, and easier to implement than many advanced methods

Cons:

- Leaves unfermented sugars behind, increasing the risk of spoilage or refermentation in package

- Pasteurization or other method of stabilization is required to prevent refermentation

- Requires tight control over process variables and packaging for best shelf stability

Best For: Brewers who want a cost-effective, scalable solution for NA beer production—especially those ready to dial in their process and manage packaging stability for distribution.

Additional Resources:

→ Learn from our experts: Basic Maltose-Negative Yeast Approach

→ Download the Fermentis BrewHacks: Complete Solutions for Low and No-Alcohol Beers

Arrested Fermentation Method

An easy-to-implement process that can be used to run trial batches, but has been replaced by newer methods that produce more consistent, better tasting products

Overview: Start fermentation as usual, then stop it before the yeast produces significant alcohol. This is often done by rapidly chilling the beer or removing the yeast early.

Pros:

- Uses standard brewhouse equipment

- Simple process to start with

Cons:

- Leaves a lot of unfermented sugars, making the beer taste “worty” or overly sweet

- Leaves unfermented sugars behind, increasing the risk of spoilage or refermentation in package

- Pasteurization or other method of stabilization is required to prevent refermentation

- Requires an efficient heat exchange system to chill the beer to effectively stop fermentation

- Can lack body and aroma

Best For: Brewers just starting out or making small test batches. Not recommended for shelf-stable, commercial products without additional controls.

High-Temp Mashing Method

A simple and inexpensive option that can be used in combination with other methods, but not ideal for brewers aiming to create standout, flavorful beers

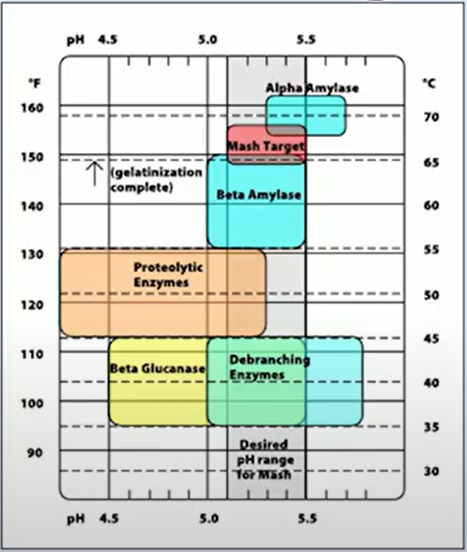

Overview: Mash grains at a much higher temperature (75-80°C) above the beta- and alpha-amylase range to create a wort with very little fermentable sugar. Yeast can ferment as usual, but with little alcohol produced.

Pros:

- Inexpensive and simple; uses existing brewhouse

- Can combine with other methods for added control

- Creates a wort that is less prone to re-fermentation

Cons:

- Risk of thin body and bland flavor

- May still need specialty yeast or flavor additions to achieve best results

Best For: Brewers who want an easy-to-implement NA process and are willing to experiment with malt and adjuncts to improve mouthfeel.

De-Alcoholization Method

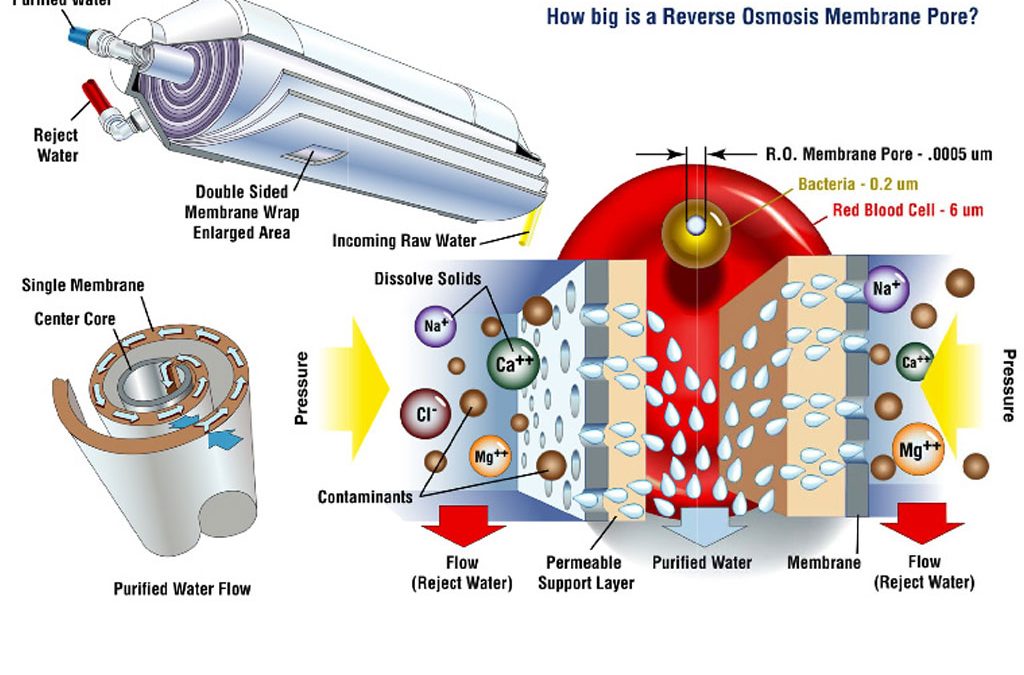

Vacuum Distillation, Reverse Osmosis Membrane Filtration, etc

An efficient and reliable production method that produces authentic flavors, but requires significant investment in equipment or a contractor

Overview: Brew a normal beer, then remove the alcohol by physical means—most commonly vacuum distillation or reverse osmosis (RO).

Pros:

- Produces NA beer with authentic, typical beer base

- Can be used to make a wide range of beer styles

- Alcohol removed during processing can be used for other products

Cons:

- Requires significant investment in equipment (deaerated water system, vacuum distillation equipment, etc)

- Not practical for most small/medium breweries who do not invest in specialized equipment, unless they want to hire a 3rd party to perform the de-alcoholization process for them

- Alcohol removal can strip volatile flavors and aromas if not handled carefully

- RO and distillation systems require specialized operation and maintenance

Best For: Larger breweries, or those planning to scale NA beer production and invest in specialized technology.

Cold Contact Method (Advanced)

A somewhat advanced method for producing NA beers that requires some special equipment and strict process control

Overview: Using a cold-temp tolerant yeast such as Torulaspora delbrueckii, the beer is fermented at very cold temperatures to minimize the yeast’s ability to produce alcohol

Pros:

- Produces NA beer with reduced aldehydes, which contribute to wort-forward flavors

- Can be an effective way to ensure your NA product maintains a fuller, cleaner flavor

Cons:

- Requires specialized processes for maintaining yeast suspension during fermentation

- Requires meticulous control over fermentation processes, and can be a complicated approach for those attempting their first NA beer

Best For: Larger breweries, or those with dedicated resources available to manage cold contact fermentation methods with consistent results