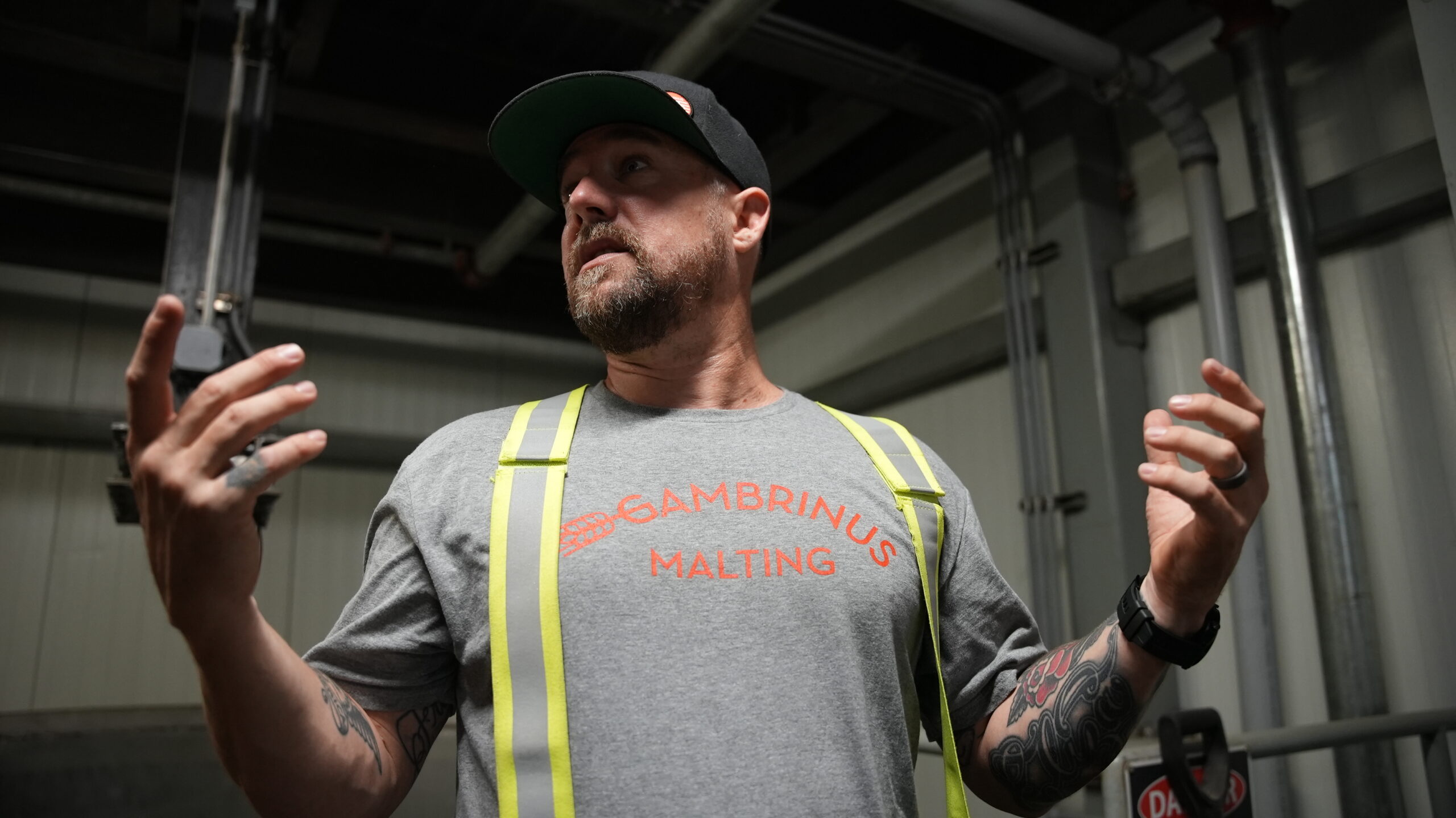

Meet Your Maltster: Ken Smith of Gambrinus Malting

Founded in British Columbia’s Okanagan Valley in 1992, Gambrinus Malting is Canada’s original artisanal malthouse. Situated among the Monashee Mountains, Gambrinus uses the finest barley, wheat, and rye to produce flavorful, consistent malt for award-winning brewers and distillers across North America.

The man behind the malting operation up in Spallumcheen, BC, is Director of Operations Ken Smith. A former software developer and data analyst, Ken joined Gambrinus in 2013 – four years before Gambrinus joined the Rahr family of brands. These days Ken is all-in on employee safety, food safety, and environmental safety. Also: building up a great team and enjoying the outdoors.

Team RahrBSG traveled to BC for a few days to follow Ken around and learn more about the malthouses under his care. He took us from the steep tank to the Saladin box and even to a distillery; we learned keeping up with Ken ain’t for the faint of heart, and some of the very best malt in the world comes from British Columbia. But let’s hear it from Ken in his own words!

What Makes Gambrinus Unique?

Gambrinus follows the same typical malt process as most malting facilities: Steep, Germination, and Kiln. Among other Rahr Malting sites, however, our small batch size makes us unique.

Something else that makes us distinct is we have a single-day steep; we don’t do two steeps. Instead, we do a single immersion and then we move straight to germination in a slurry. Compared to other Rahr sites, we may have a longer germ, depending on the product that we’re working on.

For germination, we use a Saladin box like you would find in Europe [and now elsewhere in North America]. But unlike traditional malthouses, we have an upper airflow. We push air up through the bed instead of bringing it down from the top.

We as maltsters often say that moisture and heat make color. With our kilns, we’re able to produce colors upwards of 45 SRM and as low as 1.5. Something cool about our kilns is the whole floor tilts up to 45 degrees or so. The malt is able to gently slide off into the hopper below, whether it’s 20 tons, 24, or up to 29.

Beyond infrastructure and process, we’re a German-inspired Canadian maltster. What we can offer are unique malts that are made differently from other malts produced in North America. We know that our customers are very happy with what we make; and we know we can help them set their beers and spirits apart.

What’s It Like Working with Rahr?

I’m very passionate about what we do. I tell people all the time that I’ve won the career lottery and the reason why I say that has to do with the entire package I have. I work for a great company that leads us in Rahr. I have great bosses that inspire me. Rahr is really dedicated to working and improving the communities we work in, so they give me a lot of latitude in working with our community. They all encourage me to grow, and this allows me to push the staff we have here. I extend the same gratitude to all of them as a team.

I’m super excited to see this company grow. And I’m really hoping that Gambrinus will be around for at least another 30 years. My goal is to retire with Rahr, and while I work here, I’m going to do the best I can to make this place sustainable, to make it a place where people are proud to work, and to produce a product that people are excited to use.

What’s Most Important to You?

What’s important to me is human safety, food safety, and environmental safety. And so, what I get to focus on here is making sure that everyone is safe, that the food product is safe, and that we’re not impacting the environment in a negative way.

British Columbia is my home. This community is my home. And I want my kids to be able to have a place — hopefully they stay here and find their own careers in this region. If we can do it right, and we can make it a sustainable organization that treats people right, it will keep people in this region.

What Does Sustainability Look Like at Gambrinus?

We have access to an abundance of green energy, and an abundance of mountain water. We are surrounded by beautiful lakes. We have access to some of the most pristine areas in Canada. Malting is inherently heavy on natural resources, including water. As a result, we want to make sure that we’re doing our part to reduce our water needs.

I’m happy to say that in the past year, we’ve effectively reduced our total water consumption by about 30 percent. We didn’t have to even introduce very complicated tools. Our steep tank being the biggest consumer of water, we introduced fairly simple technologies into the steep tank to make improvements. A nice benefit of using less water is less cost, but the true motivation is to reduce our impact on our community, on the environment as a whole, and make us more sustainable.

Another way we save water is by giving our wastewater a second life. About 15 years ago, Gambrinus developed an aeration pond. The wastewater from our malting process comes in through the south side of the pond and goes through an aeration element into the settling side. We’ve created a habitat for plants and bugs and other wildlife. And then all that water is given away for free to the farmers in the valley around us. The farmers typically use it for irrigation, for animal feed like alfalfa, and they are incredibly grateful. It works out really well for us and gives a useful second life to all of the water that we use here.

What Happens to the Grain You Don’t Use?

Most of our byproduct that we produce, we want it to find a home that isn’t a landfill. We work with local farmers to provide them with some of our byproduct, what we call screenings, to use for animal feed. We have some that might touch the ground or fall in the ground; we don’t want to give that necessarily to animals. That will be used for compost. We also have the wet byproduct that we pull out of the germination vessels and sometimes out of the kiln, and we give that to pig farmers. Apparently, pigs love the stuff, especially the Honey Malt. The pigs fight over that stuff. So we have very, very little waste that actually makes it to the landfill.

Could You Walk Us Through the Malt Produced Here?

Gambrinus is a specialty malthouse, but we also produce a variety of base malts. Pale and Pilsner are still two of our primary products. Our light-colored Pilsner is German-inspired and definitely a flagship product of ours.

We also have Honey Malt, which kind of put us on the map. It’s a unique product to Gambrinus. There have been attempts to simulate it in the market in the past — we believe unsuccessfully. Honey Malt continues to be a strong part of our portfolio.

But because we are a small malthouse, Rahr has helped us home in on our capabilities in terms of R&D. In the last few years, we’ve been really focused on adding value to our industry. We started off with a Rye, we added Honey Oats, and then most recently we’ve added IPA Malt and Mars red malt.

And the IPA Malt, from our perspective, is a malt that is primarily used for a single ingredient, light-colored West Coast IPA malt. So far, we love how it’s going. We’re hearing lots of kind words around using the product, so we’ll continue to work on that.

Beyond those core products, we also have an ESB Malt, which is one of my favorite malts. We have a Vienna, a Light Munich, and a Dark Munich. And we have organic products

Finally, we have one malt that’s specific to our region in British Columbia, our BC Pale Malt. This is mainly used in distilling, but there are a few breweries that use it as well. In our province, the government has offered a tax incentive to distilleries that are using 100 percent BC agricultural inputs, so we developed this product a few years ago for the BC distillers and brewers who are interested in a BC line of products.

Always Looking for Ways to Improve

We have a state-of-the-art facility. We have a well-trained staff, excellent equipment, great communication, and resources from across the entire Rahr network.

One of the first big investments that Rahr made into our facility right out of the gate was a new laboratory. Our original lab was in one of the malthouses. A laboratory has a lot of very sensitive equipment that is calibrated to a very finite level. Malthouses are loud and they’re moving; it makes it very hard for a laboratory to have reliable, consistent readings on their equipment.

And so, we moved that laboratory out of there into a different facility, which is essentially a standalone trailer located outside of House #2. Its footprint is 4-5 times larger than we had before, and that has allowed us to invest in even more equipment.

When Rahr first bought us, we were doing 8 to 10 tests, only on product. Fast-forward to today and we’re doing over 30 different analyses on both malt and barley. All of our incoming barley is now tested onsite, so we can make sure that the barley we’re receiving is the barley we were expecting. If the truck sample is what we expect in terms of cleanliness, viability, proteins, and moisture, then we can unload it. We avoid so much unnecessary risk thanks to these procedures.

Our malt samples also undergo rigorous testing. For our customers we provide COAs that include, but are not limited to, FAN, DP, proteins, color, moisture, Kolbach value, extracts, and more. We rely on the data coming out of the lab to help us pivot in the malthouse in real time each day. It has also allowed us to become that much more consistent and reliable. And ultimately, this information allows brewers to pivot in the brewhouse if they see the need.

Go Deeper:

Roll Out the Red Carpet with Gambrinus Mars Malt

Red Malt Supreme: Summit Brewing Explores Mars with Gambrinus Malt